- info@netclean.com.tr

- +90 312 473 54 54

Vacumaster and Vacumaster G in Accordance with ADR regulations

Cleaning work

The clearing/disposal of liquids is often a complex and therefore very problematic undertaking for companies engaged in this task. High-performance suction vehicles are used for the economical disposal and transport of solid matter found in sewers, drains and wells.

How can jobs such as the following be solved without losing sight of the need to maximise performance and profitability?

• Clearing of faecal matter and sewage sludge

• Cleaning of grease traps

• Pond sludge disposal

• Cleaning drains

• Cleaning grit chambers

• Cleaning sewers and drain piping up to a nominal diameter of 800

• Cleaning large ducts with a nominal diameter greater than 800

• Cleaning the ducts in landfills and sewers

• Special applications

Our Solutions

We offer the VACUMASTER for the collection and transportation of liquid waste that is not subject to any kind of regulation, and the VACUMASTER G for the collection and transportation of liquid waste that is subject to regulations, under both normal and special conditions.

Our VACUMASTER model resolves essential clearing tasks on account of its numerous technical features and details that have proven effective in many services. The most relevant functions and equipment are detailed below. We are happy to provide a more detailed and practical description of our vehicles.

The VACUMASTER G is a suction and pressure tanker as per GGVS (German regulation concerning the transport of hazardous goods by road) and ADR (European agreement concerning international carriage of hazardous goods by road) for the collection and transportation of liquid waste subject to both ordinary and special regime regulations. We offer a large number of models that can cover the following applications in addition to conventional functions:

• Cleaning of oil separators and grit chambers

• Clearing/disposal of dangerous goods and materials resulting from breakdowns

• Industrial cleaning

• Special applications

Depending on the goods transported and their corresponding goods classifications, only authorised materials that have sufficient thickness will be used for the construction of the superstructure, taking into account the GGVS/ADR regulations and standards as well as the compatibility of different fuels and sealants.

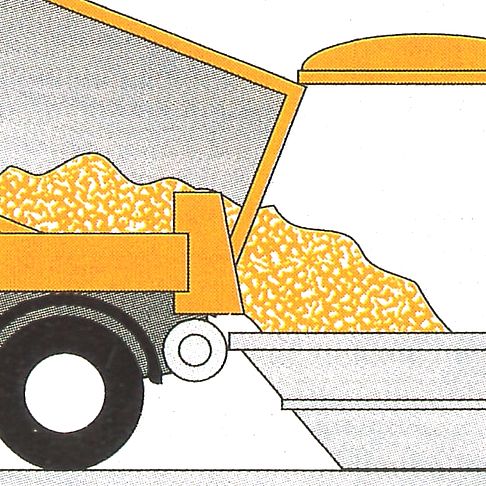

When emptying the VACUMASTER, in principle one of two methods can be chosen: either tilting the tank (tip emptying) or discharging by pneumatic piston (forced emptying). The use of water drainage devices before discharge allows almost complete drainage of the waste material.

The VACUMASTER is of course also subject to our philosophy, which applies to all our products, that customer requirements determine the functionality of each vehicle. To achieve this, we offer a wide range of special fittings and additional equipment - which also means that no two VACUMASTER vehicles are the same!

VACUMASTER G as semitrailer for tractor trucks

For special services related to the clearing and transport of liquid waste subject to regulations under both the normal and special regime, we also offer the VACUMASTER or VACUMASTER G as semitrailers for tractor trucks. This special superstructure is suitable in particular for:

• emptying sewage treatment plants

• emptying digesters

• emptying grease traps

• emptying oil and gasoline separators

• disposal of sewage sludge

that subsequently require transport over a longer distance.

VACUMASTER as a trailer and as a multi-tilt system

For particularly flexible operation during the clearing and transportation of liquid waste, we offer a trailer and also, if necessary, a VACUMASTER with a multi-tilt system. A trailer offers the following advantages:

• It can be used as interim storage

• Its use is extremely flexible

• Low maintenance costs

• Increased transportation volume

• Light inherent weight (with no high-pressure pump / with no vacuum pump)

• Allows different tractor trucks

A multi-tilt system has the following advantages:

• It can be used as interim storage

• The carrier can switch quickly between solid and liquid waste (or service in winter)

• It works on the carrier vehicle or trailer and, with an additional engine, as a fixed device

• Low maintenance costs

State-of-the-art technology, maximum functionality and proven profitability are the most relevant criteria for the purchase of suction and pressure tankers. As an internationally-operating company, we offer our customers the highest quality with regard to the superstructure as well as other important points:

• Individual systems and special superstructures

• A convincingly designed product for each form of use

• Non-contaminating manufacturing materials and methods

• In-house quality assurance as per ISO 9001

• Efficient after-sales support through an international service network